Our research portfolio

Schwerpunkte der Forschungstätigkeiten, die aktuell von den wissenschaftlichen Mitarbeitenden betreut werden, sind thematisch in diesen folgenden Themenfeldern geclustert. Einige wesentliche Projekte, die aktuell durchgeführt werden, sind nachfolgend dargestellt:

Aufbereitung von Produktionsrückständen und Altanlagen

EURO-TITAN

Decarbonized Titanium Recovery from Aluminium and

Titanium Production Residues

REMINTA

Recycling mineralischer Fraktionen aus Tailings am Beispiel des Bergeteichs am Bollrich in Goslar

ZeroSteel

Decarbonisierte Stahlproduktion durch neueartige Prozesse

Recycling von Hightech EoLProdukten

CircularLIB

Ausbildungsverbund zur zirkulären Herstellung und Nutzung von

LithiumIonenBatterien

Harmony

Holistic Approach to enhance the Recyclability of rareearth permanent Magnets Obtained from aNY waste stream

LiBinfinity

Entwicklung eines ganzheitlichen und nachhaltigen Recyclingansatzes für LithiumIonenBatterien (LIB)

ProREC

Neuartige Prozesse während des Recyclings von wässrig prozessierten und zukünftigen Batterien

Bildung für nachhaltige Entwicklung

DBU-C-EKolleg

DBUInitiative für Wirtschaft und Gesellschaft der Zukunft

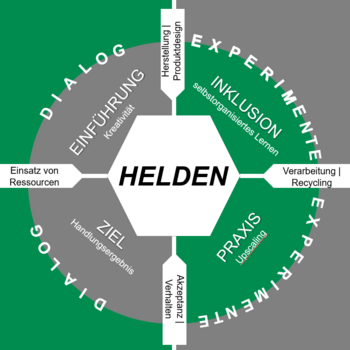

HELDEN

Rohstoffretter und Recycler der Zukunft – Helden

Entwicklung der Circular Region

Kreis

Circular Economy menschengerecht gestalten

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/6/csm_duesenfeld_jun18_099_lowres_c3bb08f706.jpg)